TARGET 161123

THE KARABA BRICK QUARRY

Bricks are usually molded from clay, but in Karaba, a small African village in southwestern Burkina Faso, bricks are quarried out of the hillside. This hill is made of laterite, a reddish-colored rock rich in iron and aluminum.

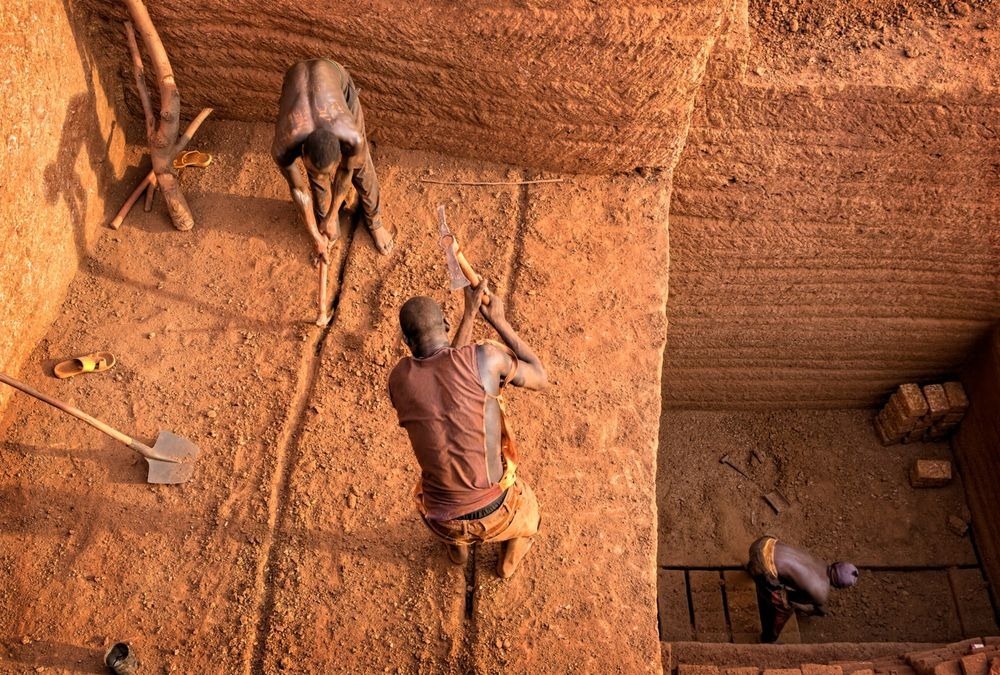

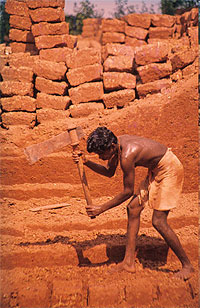

Laterite can be cut easily with a spade when itís wet and soft. When the bricks dry, they harden as the moisture between the flat clay particles evaporates within the stone and the larger iron salts lock into a rigid lattice structure.

Laterite was first described and named by the Scottish geographer Francis Buchanan-Hamilton when he discovered laterite formation in southern India in 1807. He named it laterite from the Latin word "later", which means "a brick".

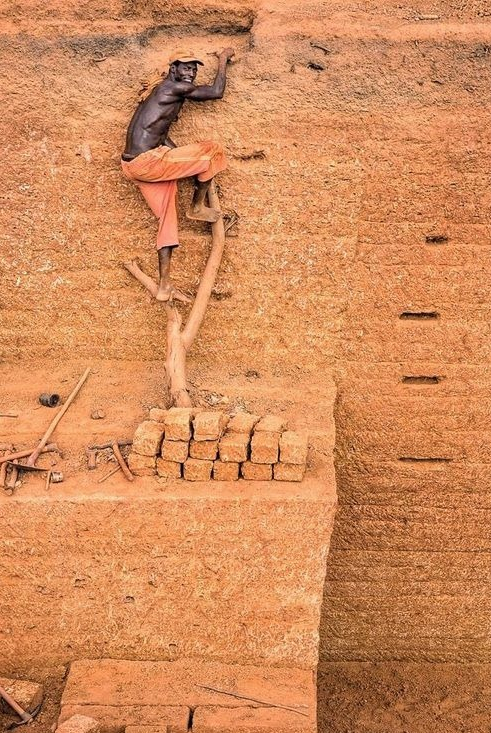

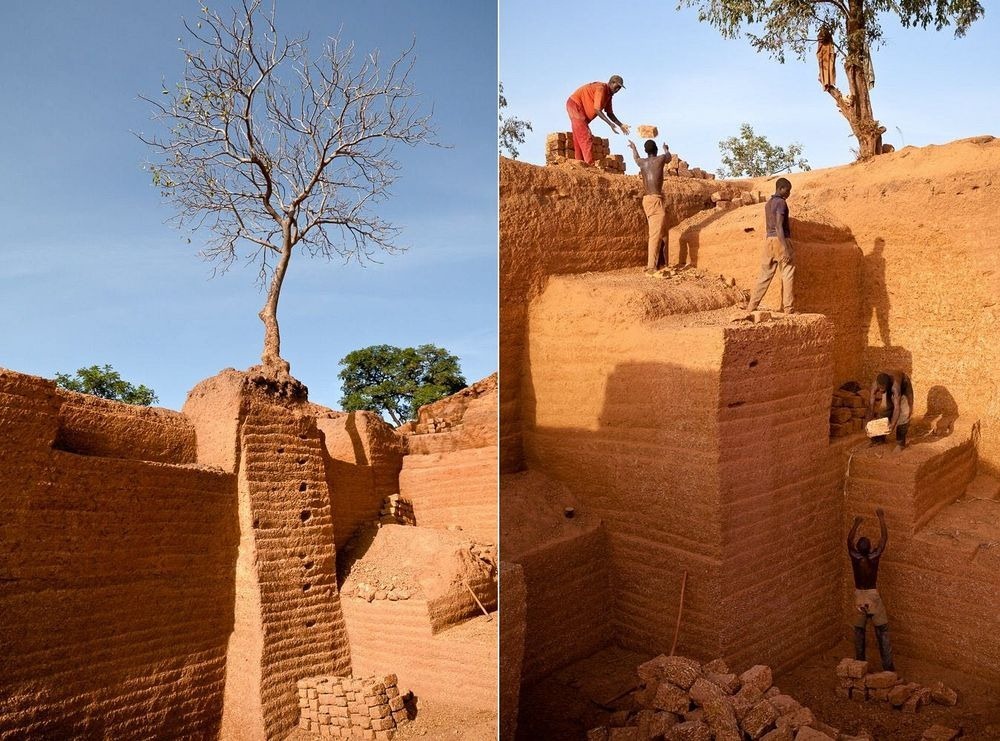

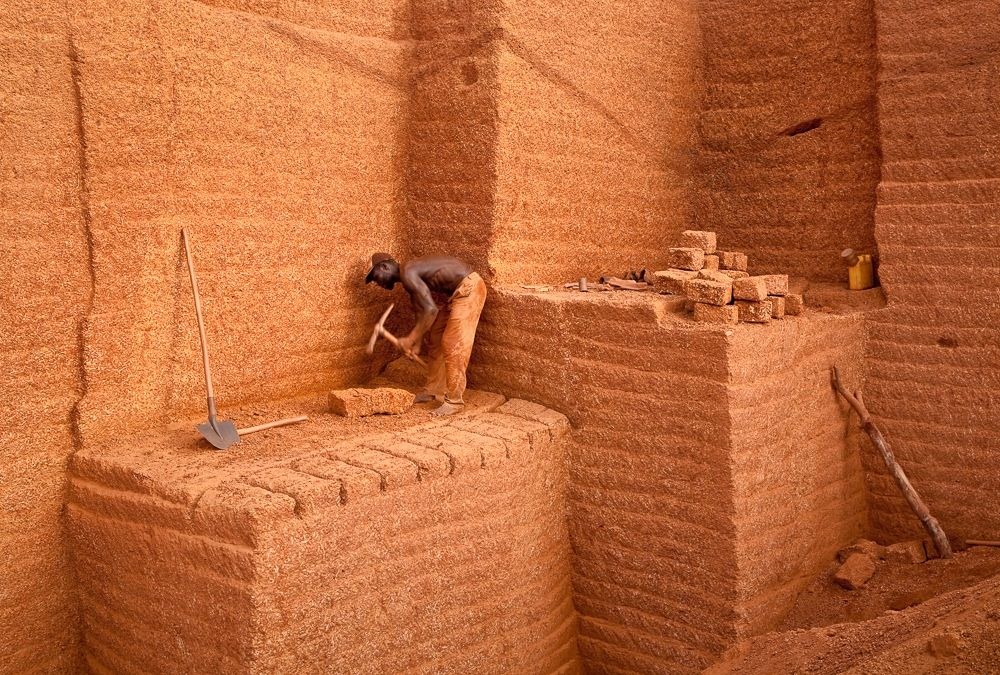

The laterite brick quarry in Karaba has been operation for nearly thirty years. Using only picks and shovels, workers carve bricks from the solid rock and over the years, the quarry has become deeper and deeper. Now, the workers carve platforms in the walls allowing them to work the sides, making the quarry wider and wider.

The workers sell the bricks in nearby villages to be used as building blocks for the homes and walls surrounding the communities. When the rock is wet and then allowed to dry, the bricks become as hard as any other brick you will find. In fact, in many places in Africa and India, they have replaced stone for road building because they are more durable.

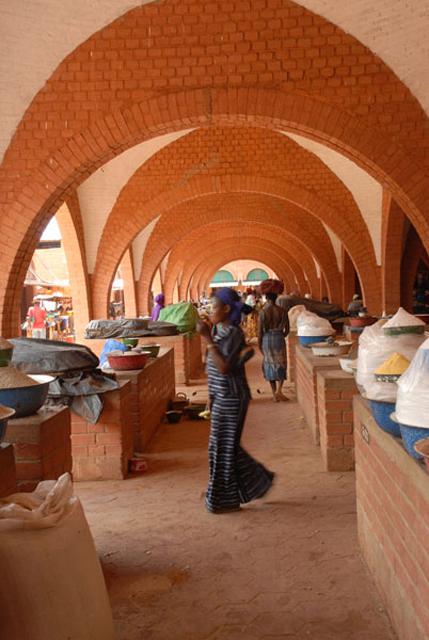

And when used in construction, they have an unrivaled strength and beauty.

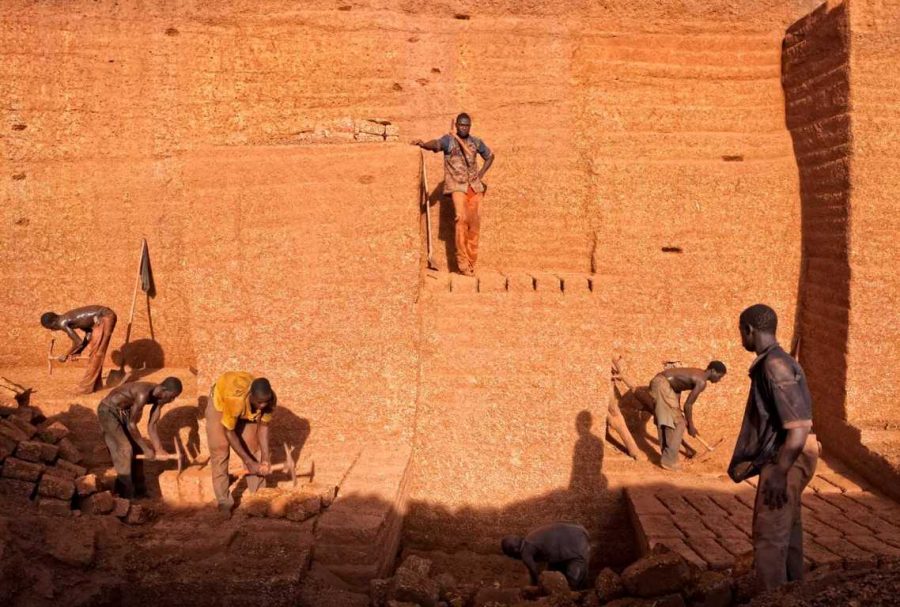

When one goes to this part of Africa, an almost unnoticed aspect is the number of laterite bricks that make up almost every structure in a town - each brick having been made by hand, one brick at a time. There are no machines which do this work.

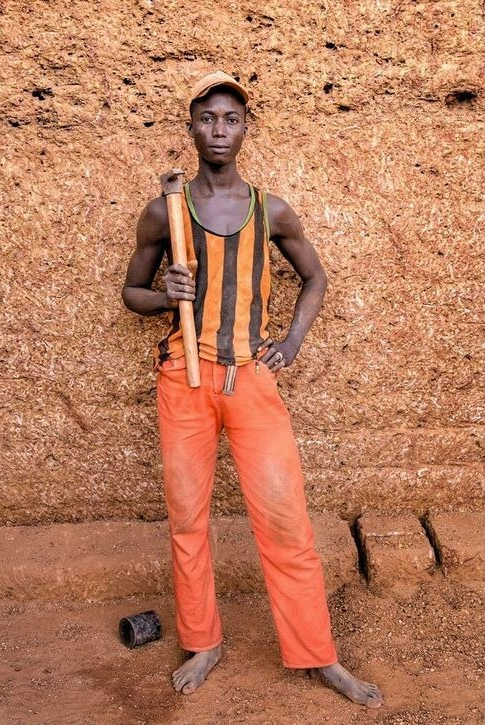

Every day, laborers go to the quarry with their picks and flat-bladed spades, sometimes ones that they have made by themselves, and spend the day making the bricks by hand. They stay in a bent-over position from the beginning of each work day to the end.

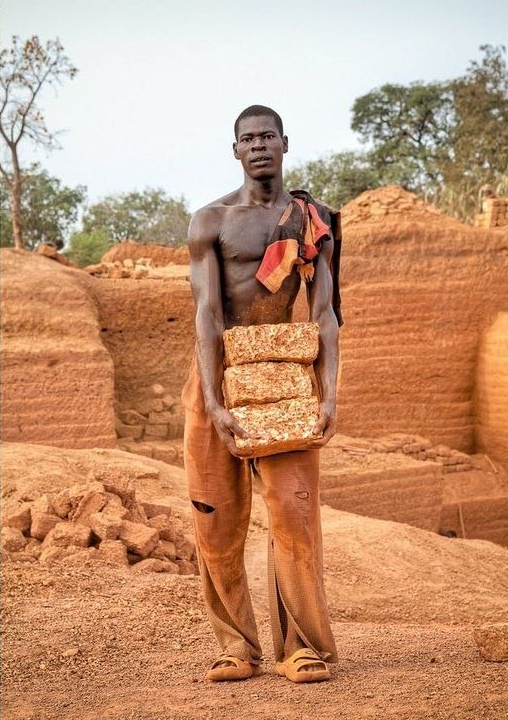

Each brick is large, heavy as any other rock that size, and the labor is never easy. But it feeds their families. The workers are not paid. Instead, each man is allowed to sell the bricks and earn the profit from the bricks he has made.

And it produces a product of which they can be justifiably proud. Each day, as they return to their village, they can see how much everyone depends on their handiwork.

FEEDBACK MAP

If you got impressions for which this feedback is insufficient, more information,

pictures and videos can be found at the following web sites:

Amusing Planet website

National Public Radio web site

ArchNet.org

David Pace Photography (provided most of the pictures shown)

Many thanks to David Pace who took these amazing photographs of a target that most people don't even know exists.