TARGET 101027

Cementing a Floor

The poarch which had no floor

Well, we had saved and saved, and finally we could close in a framed poarch at the back of our home. (By the way, the roof of the poarch is supposed to be sloped because when it rains in the desert, it pours.

To our suprise, the construction people closed in the area --before-- they put in a floor. Personally, I would have put in the floor and then closed the poarch in around it. But no, that doesn't seem to be the way it is done. They build the structure and then bring a cement truck up to it in order to dump the cement in through a window, using a long chute at the rear of the truck.

Ah, but no construction job is without its problems.

The problem

As the cement truck backed into the yard towards the poarch, its rear wheel ran directly over an unknown, underground cavity. The immense weight of the truck caved the ground in and the truck couldn't move any closer to the poarch. It was stuck. But there wasn't time to get the truck out of the hole because the cement has to be delivered and laid down before it can set. Time was of the essence.

Getting the cement out of the truck

So, they decided that the cement would need to be moved from the truck to the poarch one wheelbarrowful at a time (we only had one wheelbarrow). But the truck was tilted over onto its side, so the cement had to be moved into the chute and then shoveled into the wheelbarrow.

The cement was ported to the poarch one wheelbarrowful at a time.

One of the workers happily (HA!!) took the wheelbarrow back and forth between the truck and the poarch until the whole load was transported. We figure it took about 45 trips. And that wheelbarrow full of cement is H E A V Y !!!!

Smoothing the cement into place.

Each wheelbarrowful was rolled in through the door. Dumping the cement started at the far side of the poarch, where it was vibrated by hand, using trowels, to get the air bubbles out, and then smoothed down into a flat surface.

Working their way back towards the door.

Just the same as painters, the workers work their way from the far side of the room towards the door, so as not to trap themselves inside the room, waiting for things to dry.

The smoother on "floats"

Once the cement is de-bubbled and smoothed into place, a final surface needs to be made. A reddish powder is spread across the the wet cement by hand, and then a worker, wearing "floats" carefully moves out onto the smoothed floor and uses polished smoothing tools to both mix the powder into the wet cement and put a final polish onto the surface.

One section finished - two to go.

Because cement expands and contracts with both heat and humidity,any large piece of cement must be separated into smaller sections, with expansion room in between. That's why a sidewalk has all those sections in it. The poarch was segmented into three sections. Shown above is the first section finished, and the workers moving on to the next one.

Working the cement into corners

You can see in the picture, above, that the depth of the cement is about four inches (around 10 centimeters). The workers spread the cement carefully into every corner in such a way that the floor would be completely level all the way up to the walls.

Finishing the project

Once all the sections are laid, smoothed, dyed and polished, the workers make a final check for any indentions and to make sure the floor is perfectly level. Again, they start at the far wall and work their way backwards towards the door. Then, about four days later, the floor is ready to have furniture moved in and be walked on.

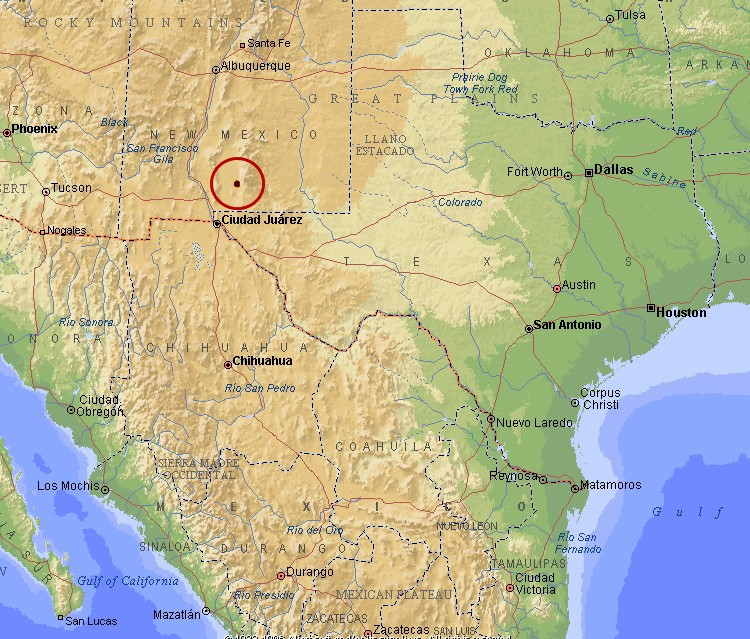

FEEDBACK MAP