TARGET 081105

The University of Florida's

Hurricane Simulator

The Huricane Simulator

GAINESVILLE, Fla. — It will huff, and puff, and blow the house in — but only for research purposes.

Two days before the June 1 start of the 2007 hurricane season, University of Florida wind engineers unveiled the world’s largest portable hurricane wind and rain simulator. Mounted on a trailer, the industrial-sized behemoth is composed of eight 5-foot-tall industrial fans powered by four marine diesel engines that together produce 2,800 horsepower. To cool the engines, the system taps water from a 5,000-gallon tank aboard a truck that doubles as the simulator’s tow vehicle.

The wind generating fans

UF civil and coastal engineers plan to use vacant homes for testing. They will blast them with winds of up to 130 mph — Category 3 on the Saffir-Simpson Hurricane Scale — and high-pressure water jets that mimic wind-driven torrential rain.

The goal: to learn more about exactly how hurricanes damage homes, and how to modify them to best prevent that damage.

“We want to conduct experiments to evaluate real homes in communities that are impacted by hurricanes,” said Forrest Masters, an assistant professor of civil and coastal engineering and the leader of the project. “This simulator also gives us the ability to test home retrofits and new building products aimed at preventing hurricane damage.”

The simulator, which cost about $500,000 in parts and labor, was designed and constructed entirely by Masters, lab manager Jimmy Jesteadt and a team of undergraduate students.

At the controls

It is one of a kind. Unlike previous, smaller simulators, the new simulator uses an innovative hydraulic system, rather than chains or mechanical drive trains, to transfer power from the engines to the fans. Designed by Linde Hydraulics Corporation and Cunningham Fluid Power Inc., the engines spin pumps, which then drive fluid through motors housed in the fans. The result is lighter, less bulky and safer than traditional drive systems, Masters said.

At full power, the fans turn at about 1,800 revolutions per minute, producing wind speeds of about 100 mph. A custom-built duct reduces the space available for the air to flow through, ratcheting up the wind speeds to a potential 130 mph. Steering vanes allow the engineers to direct the air wherever they want it to blow.

Implanted in the vanes, the water jets can simulate the most extreme rainfall of up to 35 inches per hour, although 8 inches per hour is more typical, Masters said.

The simulator is the latest addition to a growing arsenal of hurricane research equipment designed and assembled by UF wind engineering researchers trying to learn more about ground-level hurricane winds and how they affect structures. In a related project, the researchers built several portable hurricane wind monitoring towers that were deployed in the path of land-falling hurricanes in recent years.Watch the simulator in action.

“When this program first started, we brought the lab to the hurricane,” Masters said. “Now, we’re bringing the hurricane back to the lab.”

Rick Dixon, executive director of the Florida Building Commission, said state officials began to tap UF research for help in strengthening the state’s hurricane-related building codes shortly after Hurricane Andrew in 1992.

The 2004 storms showed that while improved codes were effective in preventing catastrophic building failures, challenges remained in blocking wind and water intrusion, he said. It will take more research to learn how to protect windows, doors, soffits, roof coverings and other so-called “components and claddings” – research for which the new wind simulator will be pivotal, he said.

“The test facility that Forrest has built allows us to evaluate those components and claddings and determine where they are failing,” he said. “So if the building code establishes minimum performances, than that can give us new standards for upgrading the building code.”

The cause is noble, but there’s something deliciously evil about the University of Florida’s Hurricane Simulator, with its eight 5-ft.-tall fans capable of generating 130 mph winds—equivalent to a Category 3 hurricane—and high-pressure water jets that can simulate rainfall as heavy as 35 in. per hour.

A 5000-gal. water tank cools the machine’s four marine diesel engines, which add up to 2800 hp. The fans actually generate 100-mph winds, which pass through a duct that constricts the flow of air, and boosts its speed. The Simulator has been used to test the effects of extreme rain and hurricane-force gusts on structures, and was joined by a device that launches high-speed shingles.

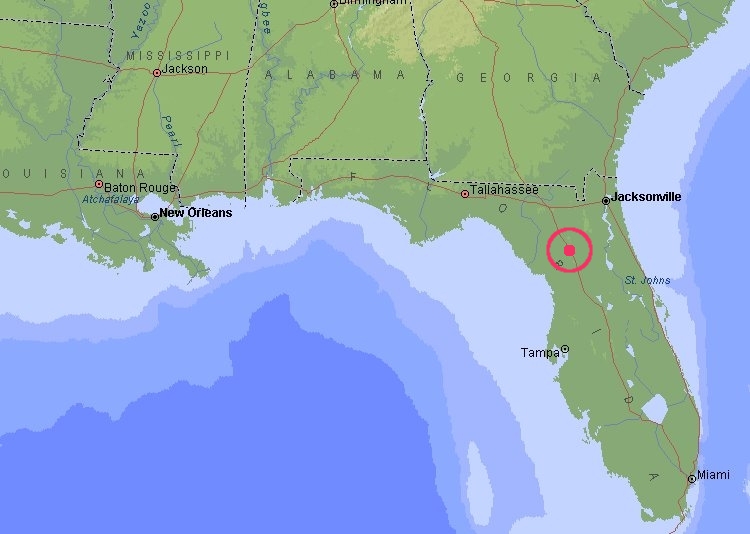

FEEDBACK MAP

If you got impressions for which this feedback is insufficient, please take a look at the following web sites for more:

University of Florida

BBC - same movie above only on the web.

Many thanks to Ray McClure for this target.